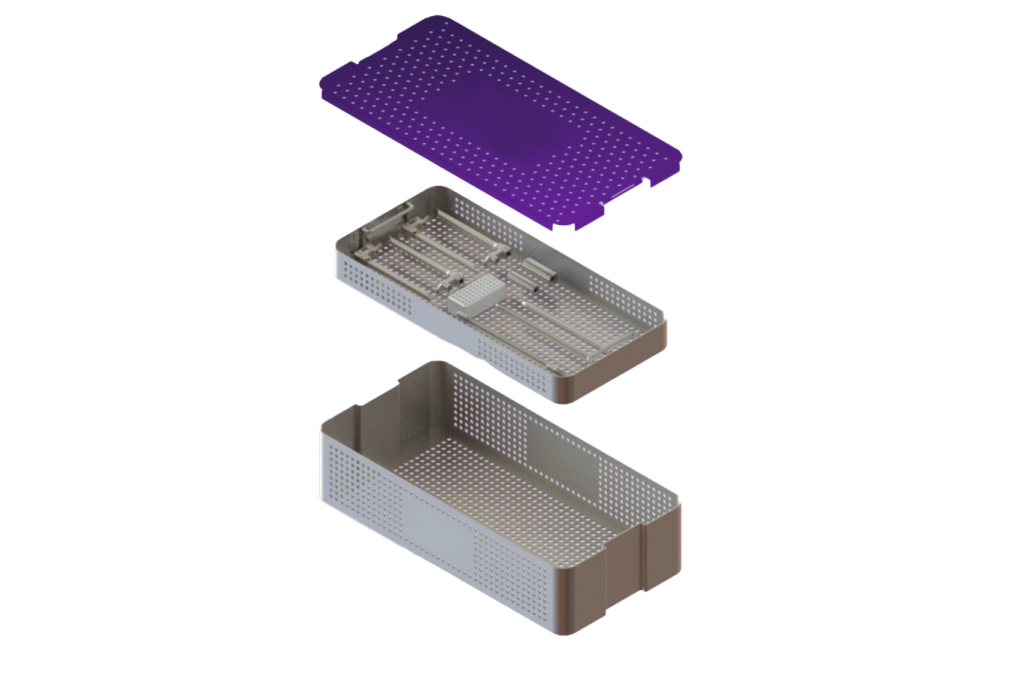

Sterilization Trays

Gizmo Medical leads the industry in sterilization tray production, offering unmatched turnaround time from initial design to finished product. Our trays are fully customizable, with options for logos, colors, and silk screening to match your needs. We also provide tailored tray layouts to meet specific surgical system needs, ensuring optimal organization, sterilization, and instrument protection.

Ratchet & Torque Handles

Our torque handles and ratcheting drivers are available in multiple styles, including palm, T-handle, and straight configurations to suit a wide range of surgical preferences. We offer full customization, including silicone color options and multi-color logo inlays, allowing you to align your instruments with your brand while maintaining ergonomic comfort and precision control.

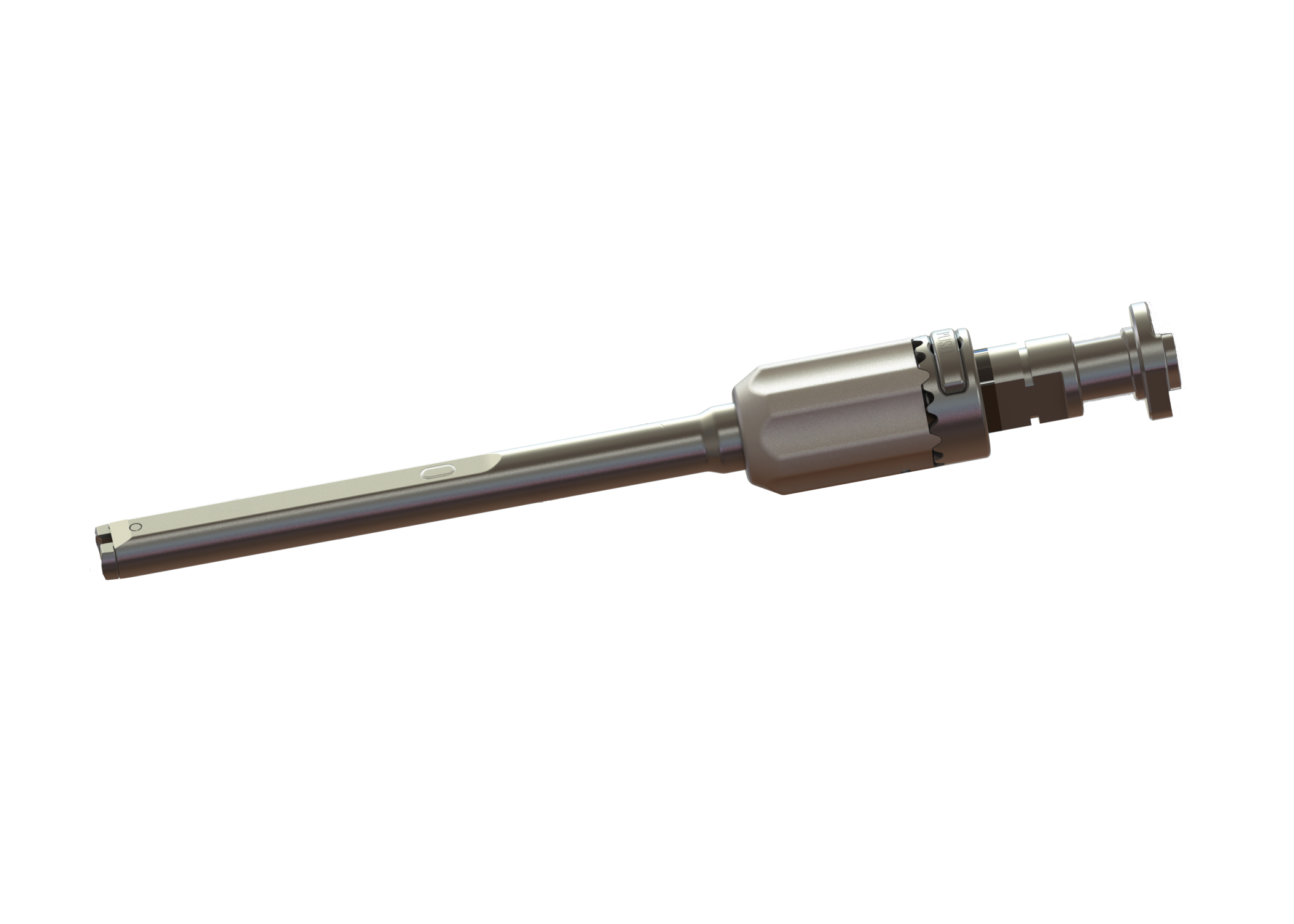

Installers & Inserters

Gizmo Medical manufactures a wide range of installers and inserters designed for TLIF, PLIF, ALIF, and endoscopic approaches. Engineered for both micro-invasive and open surgeries, our inserters deliver precise, reliable performance across a variety of spinal procedures. Each instrument is designed with surgeon ergonomics in mind, offering balanced weight, comfortable grip, and intuitive handling to reduce fatigue and improve control in the surgical field.

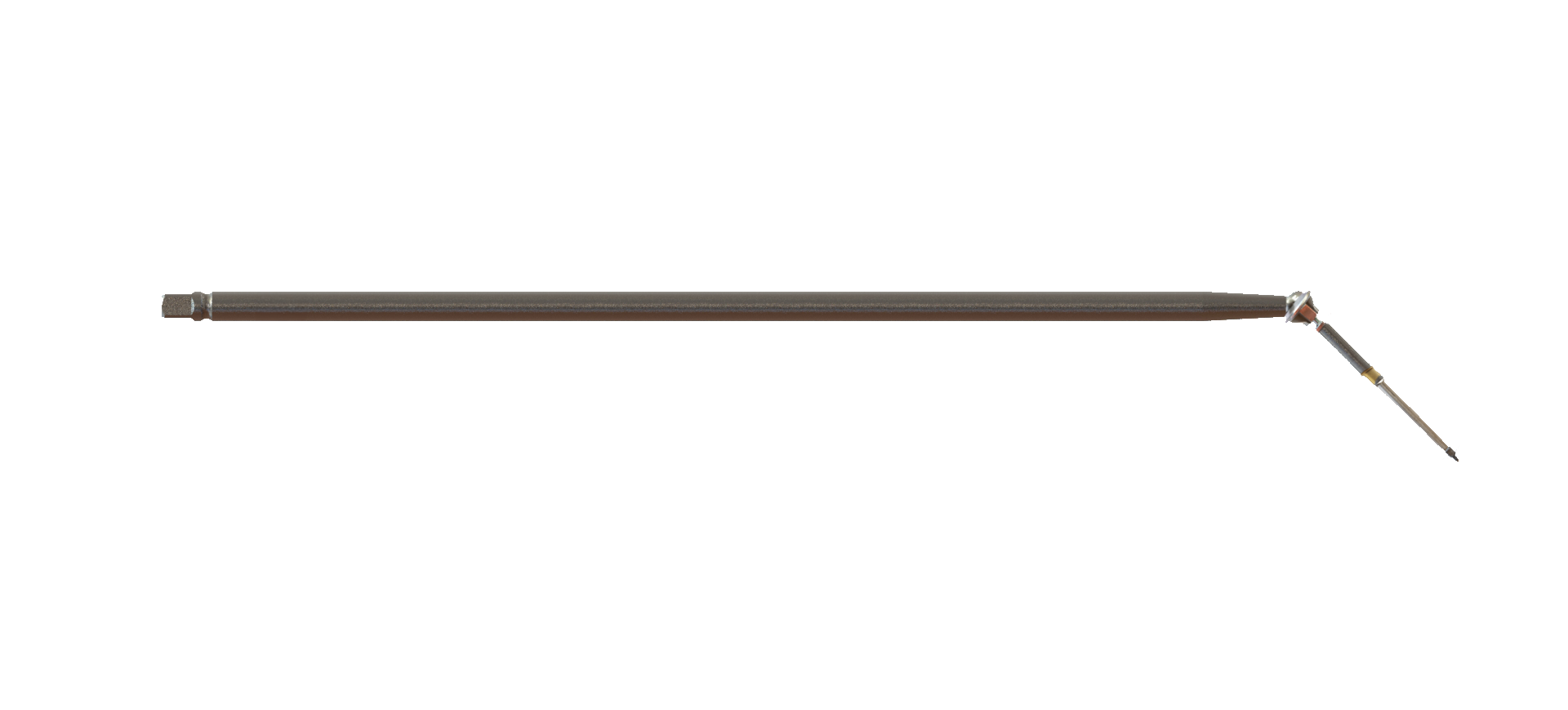

Drills & Taps

Gizmo Medical designs and manufactures high-performance drills and taps, available in both cannulated and non-cannulated configurations. We offer full customization, including anodized finishes in custom colors to support instrument identification and branding. With extensive experience in angled drill and tap designs for micro-invasive procedures—such as ACDF and SI joint fusion—as well as traditional straight configurations, our instruments are built for precision, reliability, and compatibility with a wide range of surgical techniques.

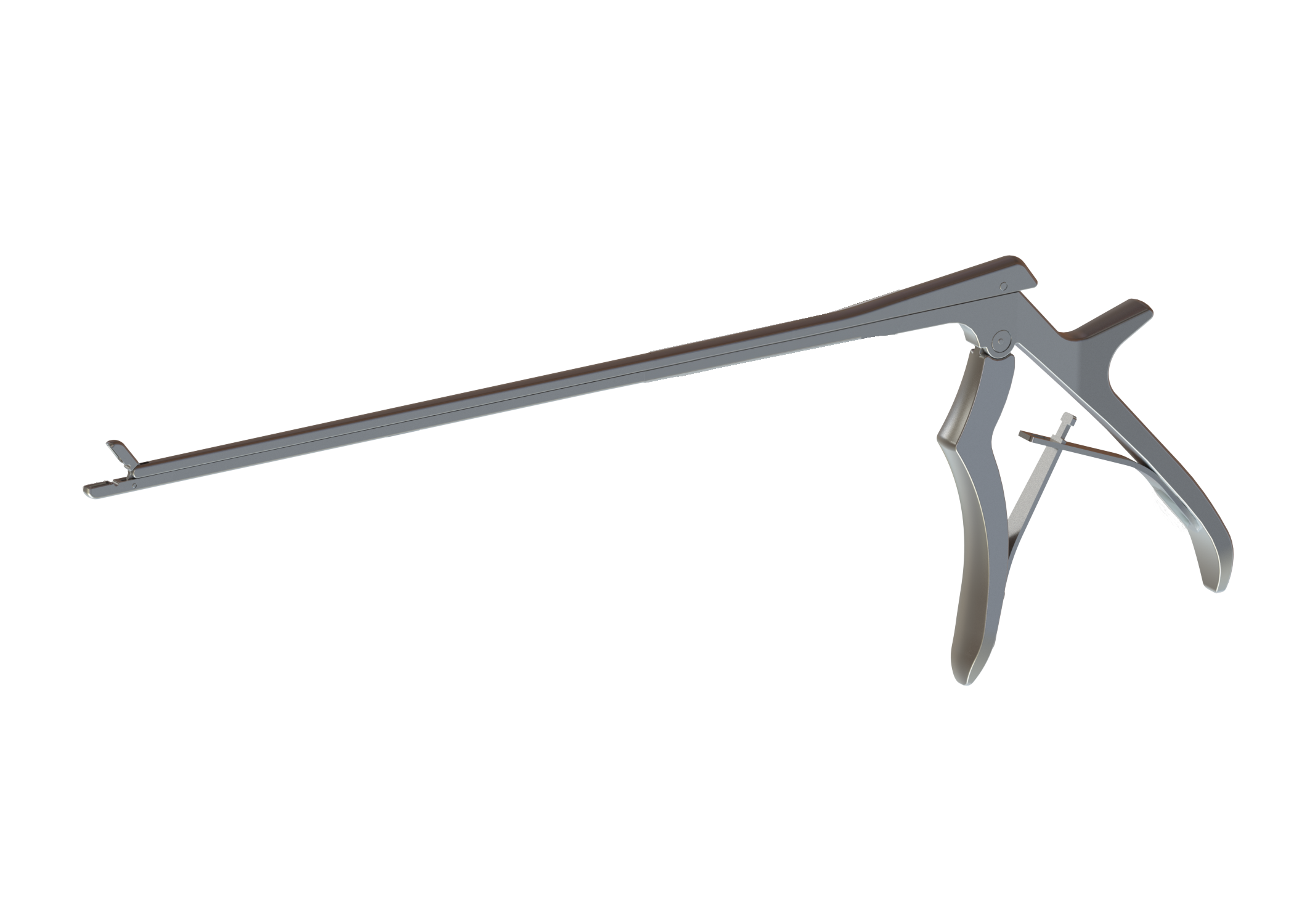

Surgical Preparation

Gizmo Medical offers a comprehensive line of surgical site preparation instruments designed for precision, control, and versatility across a wide range of procedures. Our portfolio includes pituitaries, rasps, curettes, augers, rongeurs, and Kerrison rongeurs—tools essential for effective tissue and bone preparation. Whether for orthopedic, neuro, or general surgical applications, our instruments are engineered to efficient access and site conditioning, ensuring optimal readiness for implant placement or further intervention. We also offer laser marking for part numbers, branding, or procedural identification, adding clarity and traceability to every instrument.

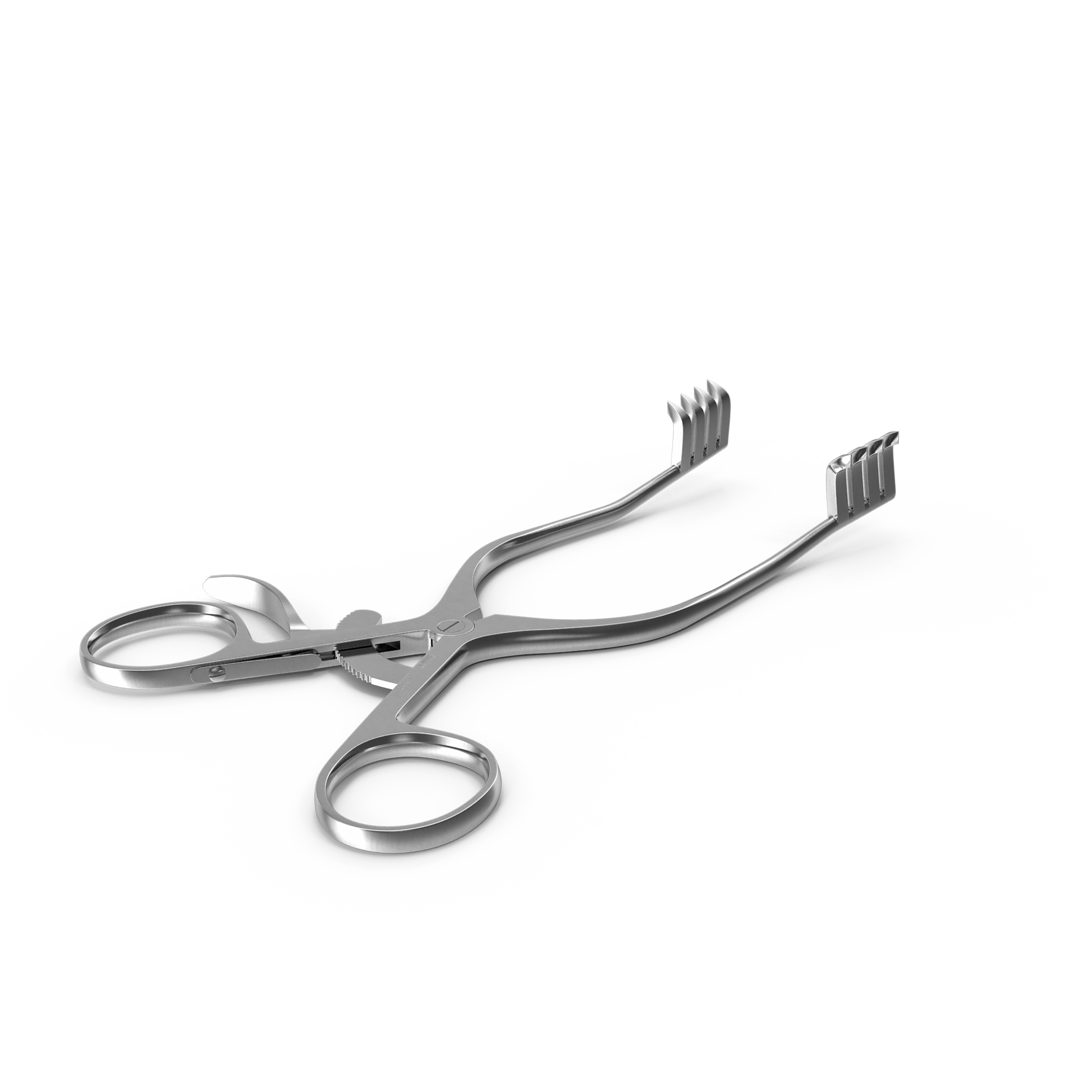

Access

Gizmo Medical provides custom access solutions, including retractors and distractors, designed to meet the unique demands of complex surgical procedures. Whether for soft tissue management or bony distraction, our engineering and manufacturing capabilities allow us to produce precision instruments tailored to specific approaches and anatomies. From single-use to reusable systems, we work closely with our partners to develop access devices that enhance visibility, control, and surgical efficiency. If you can design it, we can build it.

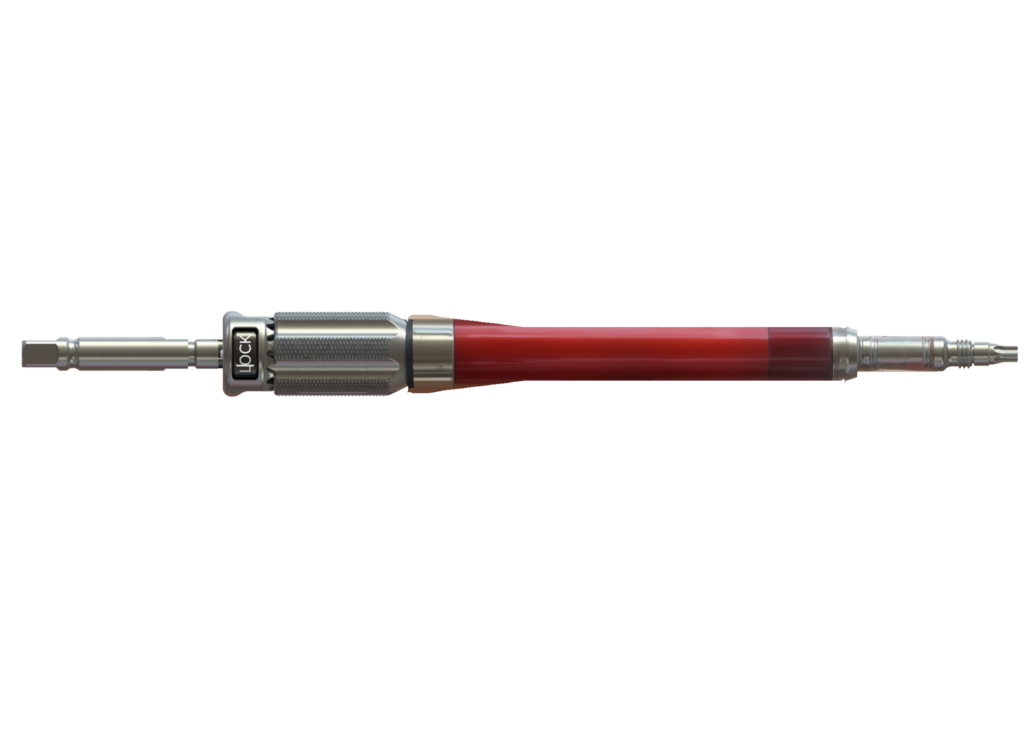

Drivers

Gizmo Medical has produced a wide range of custom screwdrivers for pedicle and SAI (sacroiliac) fixation systems, tailored to meet the demands of spinal implant procedures. From robust reduction drivers to precision torque-limiting and engagement tools, we’ve manufactured designs to match various implant interfaces and surgical techniques. Whether you’re refining an existing system or developing something new, we have the experience and flexibility to manufacture drivers to your specifications.

Prototype Implants

Gizmo Medical has extensive experience manufacturing prototype implants for testing, validation, and design certification. We’ve supported engineers and design teams with rapid turnaround times, delivering fully machined implants in days—not weeks. These prototypes are built to precise specifications and can be used for design verification, surgeon evaluation, and cadaveric implantation. Whether for functional testing, sizing confirmation, or regulatory preparation, our prototyping capabilities help accelerate development cycles without compromising quality or detail.

Material Refinement

At Gizmo Medical, we routinely collaborate with customers to optimize designs for performance, usability, and logistics. We have experience modifying material selections to reduce overall weight, helping customers lower shipping costs and streamline handling—without compromising durability or function. Enhancing operational efficiency without compromising functionality.